Release time:2023-09-15

Recently, Fudi Battery Co., Ltd., a subsidiary of Shenzhen BYD Co., Ltd., visited our company Shenzhen Fayuan with its technical department to have in depth exchanges on power battery welding solutions

During the exchange, the representative of Fodi expressed high recognition for our lithium battery welding solution Among them, our new core model, the composite current collector rolling welding machine, performing outstanding and attracting the attention of Fodi engineers We hope to further explore and exchange ideas

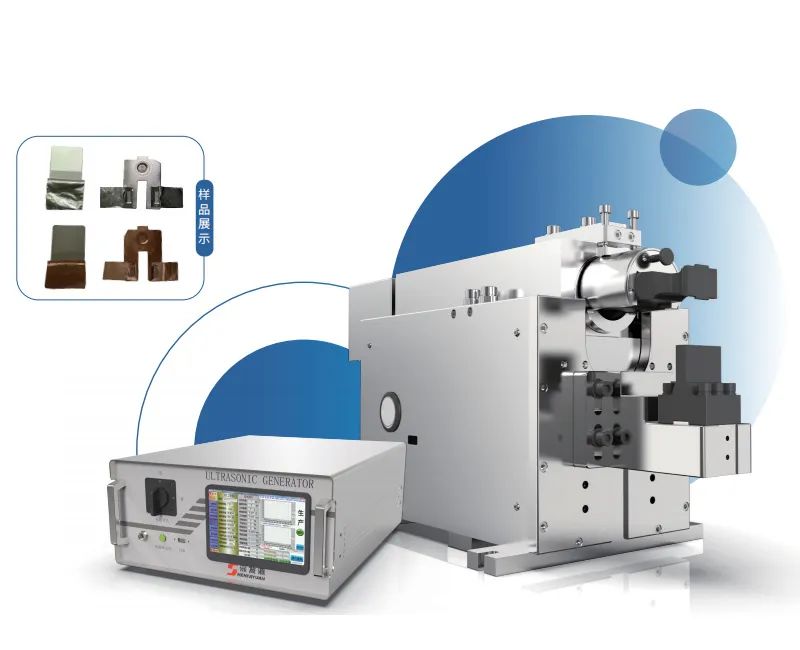

ultrasonicComposite collecting fluid rolling welding machine

The ultrasonic composite current collector roll welding machine is used for welding copper foil or aluminum foil with corresponding composite substrates, and for welding multi-layer copper foil or aluminum foil. Welding range: 2 layers of composite material, 1 layer of composite material, and 2-50 layers of conventional material. Power: 50KHZ/400W, 40KHZ/800W, 20KHZ/3000-6000W

Ultrasonic composite fluid collection rolling welding machine

? Welding data monitoring; Convenient alignment of grain parallelism

? Welding power curve monitoring; 5 million data stores

? The welding head and welding seat both adopt a high rigidity structure with two fulcrums

? Adopting Swiss SKF high rotation precision bearings and Japanese THK guide screw

For the past five years, Shenzhen has been focusing on the research and production of ultrasonic welding equipment With its rich practical experience, professional knowledge, and global resources, it provides related welding assembly solutions for lithium battery manufacturers, meets the production requirements of lithium battery products, accelerates large-scale production and market launches, and achieves expected investment returns For many years, Shenzhen has been committed to empowering the rapid development of the lithium battery industry with excellent ultrasonic metal welding solutions, improving manufacturers with more efficiency and low cost welding solutions In addition to the core model of ultrasonic composite fluid collection rolling welding machine, Shenzhen also has a series of advanced welding equipment such as 20K ultrasonic metal welding machine, 20K direct pressure ultrasonic welding machine, and servo mechanism ultrasonic welding machine

20K ultrasonic metal welding machine

The 20K ultrasonic metal welding machine adopts a German ultrasonic system, which ensures firm welding points, is not easily oxidized, has low internal resistance, is fast, safe and aesthetically pleasing, and is easy to operate. Used for pre welding of lithium battery foil, welding of foil and current collector, welding of cables and electronic components or connectors, and welding of nickel mesh and nickel sheet in nickel hydrogen batteries. Welding pole ear layer 10-80 layers, power: 3000W-6000W

20K ultrasonic metal welding machine

? Welding time monitoring, parameter setting monitoring

? Welding power curve monitoring, real-time height monitoring

? Real time pressure monitoring with built-in monitoring system

20K direct pressure ultrasonic welding machine

The 20K direct pressure ultrasonic welding machine adopts a German ultrasonic system. The design of this institution is comprehensively optimized, with more reliable mechanical stability. At the same time, based on the ultrasonic characteristics, the fixed reference of the wave generating component is used, and the direction of the load force coincides with the direction of the welding base support force. The welding head and amplitude lever have no bending deformation, suitable for high pressure welding and ensuring its stability. It is applied to the reliable welding of multi-layer pole ear lithium batteries, with a welding range of 30-140 layers of copper foil pole ear welding and a power of 6000W

20K direct pressure ultrasonic welding machine

? Easy to adjust machine, facilitating equipment maintenance and replacement of vulnerable parts

? The welding surface is uniformly compressed to ensure consistency in welding quality

? Unique actuator with concentrated force, high strength, and efficient transmission of ultrasonic energy

? Small deformation, capable of welding under high pressure and small amplitude, reducing welding material damage

Servo ultrasonic welding machine

The servo ultrasonic welding machine adopts a German ultrasonic system. The mechanism is comprehensively optimized by using servo motors instead of the original cylinders, resulting in more reliable control of the servo. The whole machine adopts pressure sensors and height sensors, which accurately combine displacement and welding to achieve higher welding quality. Welding layers: 2-40 layers, welding power: 800W-3000W

Servo ultrasonic welding machine

? All imported accessories, stable performance, faster welding cycle speed

? More stable completion of the entire welding process

? Extend the lifespan of vulnerable parts and reduce maintenance time

? Easy to adjust machine, facilitating equipment maintenance and replacement of vulnerable parts

? Controllability of motion, controlling every step of the welding process

The ending

Thank you again for the arrival of Fodi Battery, which has made our company shine brightly! This technical exchange has brought the relationship between the two companies closer, and we hope that in the future, the two companies can work together to support the rapid development of the lithium battery industry!

As a trusted partner of many leading enterprises and manufacturers in the lithium battery industry, Shenfayuan always adheres to the principle of "customer first, quality first, continuous improvement, and pursuit of excellence", committed to helping manufacturers provide ideal welding solutions, meeting the needs of lithium battery manufacturers for low cost, high production, high quality, high efficiency, and providing strong support for manufacturers to maintain a leading position in fierce market competition.

微信視頻號

微信二維碼

微信公眾號

抖音二維碼